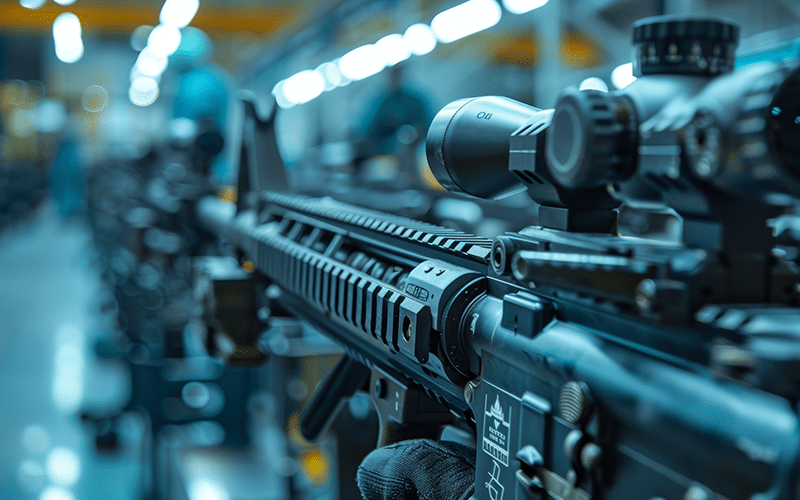

Turning for drive shafts and and armaments

We have the resources for precision machining and turning for the defence industry. The combination of our machine plant and our close relations with suppliers allows us to meet the specific constraints of this market. Our quality system complies with the EN9100 standard, meeting all the constraints relating to the manufacture of parts for the industry.

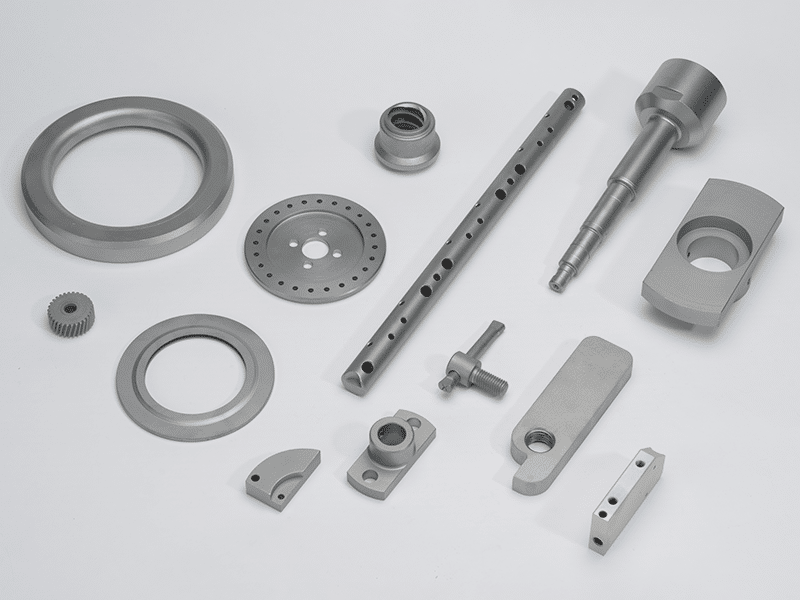

Typical parts:

1. Components for firing mechanisms

- Barrels

- Insert rods

- Breeches

- Firing pins

2. Components for aiming and control systems

- Aiming systems

- Spindles and drives

- Locking controls

3. Support and structural parts

- Assembly brackets

- Spacers and baseplates

- Gun chambers

4. Components for hydraulic and pneumatic systems

- Regulator valves

- Connector parts

- Hydraulic pumps

- Control cylinders

5. Parts for safety and trigger mechanisms

- Safety locks

- Release systems

- Triggers and releases

- Striker triggers

6. Components for aiming and navigation systems

- Sight supports

- Optical components

- Guide spindles

- Sensor brackets

7. Components for propulsion and munitions systems

- Loaders

- Cartridge ejectors

- Munitions and propulsion components

- Launch mechanisms

Inspection of machined parts for the defence industry

Our procedure includes the inspection of turned parts pursuant to the EN 9100 standard :

-

Verification of the 3.1 Material Certificate

-

Verification of lengths, diameters, threading, drill holes, tapping, radii, etc.

-

Roughness verification

-

Hardness verification

-

Surface condition verification

-

Optical inspection

-

Inspection reports

-

Measurements

-

100% control

-

PPAP/FAI

-

Cp/Cpk statistic

Turning materials for the defence industry

We use a range of materials depending on the part to be turned and its application.

-

Stainless steel (1.4305 / 1.4307 / 1.4404 / 1.4105 / 1.4057 / 1.4028 / 1.4418 / 1.4542 / 1.4006)

-

Leaded steel (S300Pb / A37Pb / C15Pb / 35MF6Pb / C35Pb)

-

Lead-free steel (S300 / S250 / S235JR / S355 / C35 / C45 / C22 / C15 / 16MC5 / 16NC6 / 42CD4 / 35NCD16 / XC10 / XC15 / XC18 / 30CND8 / 100C6)

-

Aluminium (2011 / 2017 / 2030 / 6060 / 6082 / 2024 / 7075 / 5754)

-

Brass (CuZn39Pb3 / CuZn39Pb2 / CuZn42)

-

Copper (CUA1)

-

Bronze (UE7 / UE12 / UE9P)

-

Plastic (POM / PA / PEHD / PTFE / PEEK / PVC)

-

Inconel

Turned part treatment

Special treatments can be applied to parts to give them the desired finish. We have listed suppliers for specific treatments, including:

-

Surface treatment: passivation, burnishing, phosphate conversion coating, anodizing, galvanization, copper plating

-

Thermal treatment: annealing / quenching and tempering / nitriding

-

Painting : e-coating / liquid / epoxy