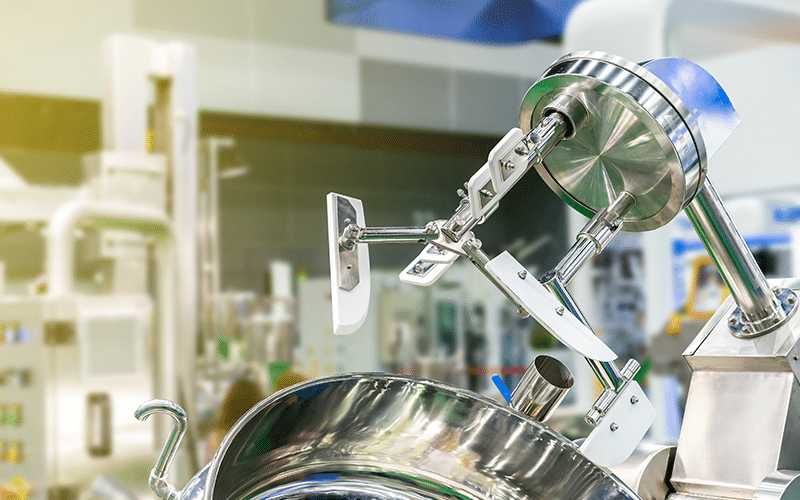

Turning for food grade parts

We have the resources for precision machining and turning for the food industry. The combination of our machine plant and our close relations with suppliers allows us to meet the specific constraints of this market. Our EN9001-compliant process includes the supply of all documentation required for part traceability.

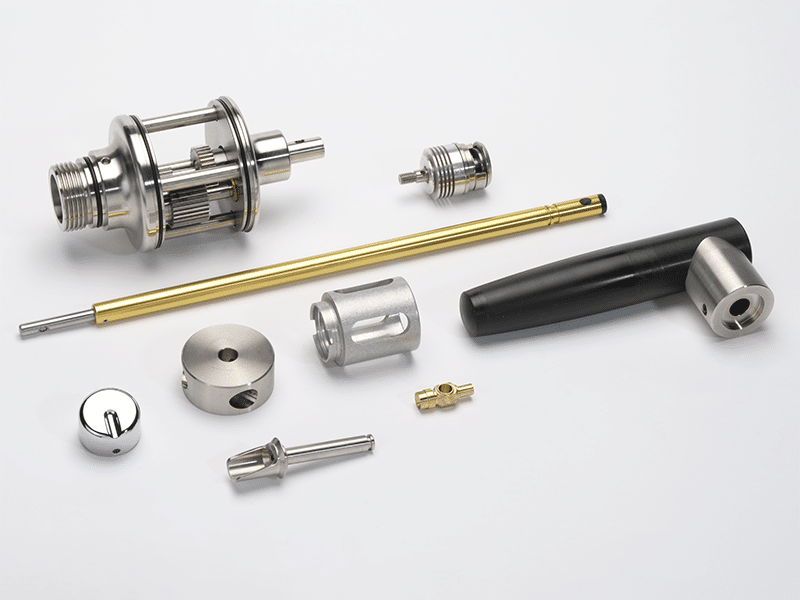

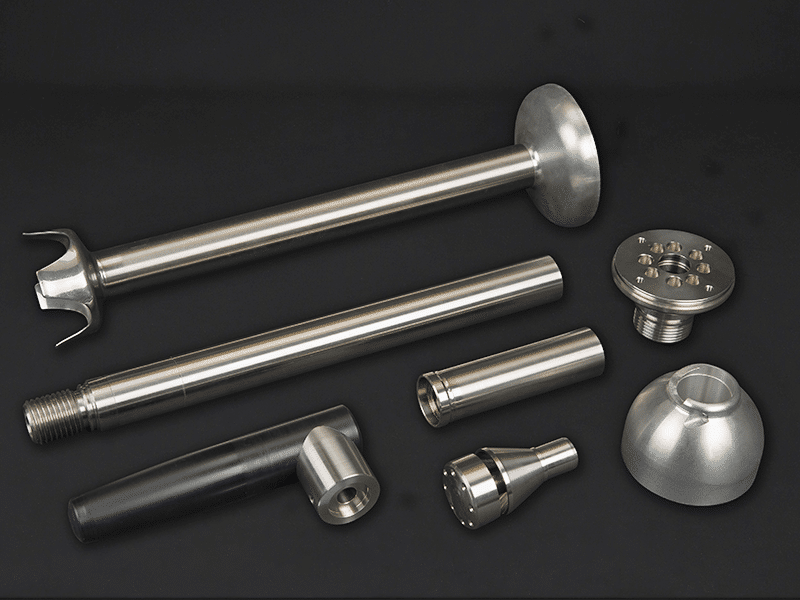

Typical parts:

1. Parts for fixings and the connector industry

- Fixing screws

-

Nuts and bolts

-

Pipework connectors

2. Components for transmissions and machinery

- Plain bushings

- Spindles

- Gears

3. Parts for design and assembly

- Plain bushings

- Linear guides

- Spacers

- Washers

4. Specific parts for equipment

- Stainless steel drive pinions

- Seals and linings

- Rods and stems

- Brackets and mountings

5. Accessories and hardware

- Headless and countersunk screws

- Mounting plates

- Threaded inserts

Inspection of machined parts for the food industry

Our procedure includes the inspection of turned parts pursuant to the EN 9100 standard :

-

Verification of the 3.1 Material Certificate

-

Verification of lengths, diameters, threading, drill holes, tapping, radii, etc.

-

Roughness verification

-

Hardness verification

-

Surface condition verification

-

Optical inspection

-

Inspection reports

-

Measurements

Turning materials for the foodindustry

We use a range of materials depending on the part to be turned and its application.

-

Stainless steel (1.4305 / 1.4307 / 1.4404 / 1.4105 / 1.4057 / 1.4028 / 1.4418 / 1.4542 / 1.4006)

-

Leaded steel (S300Pb / A37Pb / C15Pb / 35MF6Pb / C35Pb)

-

Lead-free steel (S300 / S250 / S235JR / S355 / C35 / C45 / C22 / C15 / 16MC5 / 16NC6 / 42CD4 / 35NCD16 / XC10 / XC15 / XC18 / 30CND8 / 100C6)

-

Aluminium (2011 / 2017 / 2030 / 6060 / 6082 / 2024 / 7075 / 5754)

-

Brass (CuZn39Pb3 / CuZn39Pb2 / CuZn42)

-

Copper (CUA1)

-

Bronze (UE7 / UE12 / UE9P)

-

Plastic (POM / PA / PEHD / PTFE / PEEK / PVC)

Turned part treatment

Special treatments can be applied to parts to give them the desired finish. We have listed suppliers for specific treatments, including:

-

Surface treatment: passivation, burnishing, phosphate conversion coating, anodizing, galvanization, copper plating

-

Thermal treatment: annealing / quenching and tempering / nitriding

-

Painting : e-coating / liquid / epoxy